Bob Christensen wanted something more than a job in Thiokol. In 1990, the engineer created 20 different business plans, bought an injection molding machine and decided to start his own business. He took his one machine and opened shop in a “teeny” little building behind the post office in Brigham City and he’s never looked back, according to his son and Streamline Plastics General Manager Jeremy Petersen.

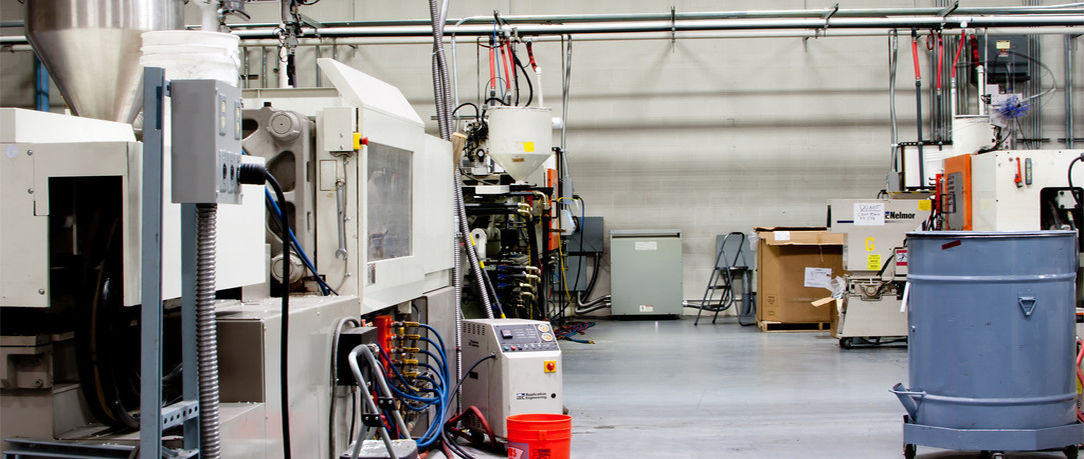

Bob Christensen wanted something more than a job in Thiokol. In 1990, the engineer created 20 different business plans, bought an injection molding machine and decided to start his own business. He took his one machine and opened shop in a “teeny” little building behind the post office in Brigham City and he’s never looked back, according to his son and Streamline Plastics General Manager Jeremy Petersen.

Now they have 11 machines and two blow molders and had to move twice to find a big enough facility to meet the growing demands of their fledgling business.

Not long after Christensen opened his first shop in Brigham City, he moved to a space at the Indian School in Brigham City – he needed more than two machines. Soon, they grew too big for that space and needed to expand. They tried to stay in Brigham City, but ran into snags with building approvals. Plus, they had a need to move closer to the Ogden/Salt Lake City area where a bulk of their business seemed to be. It was a natural fit to move to the Industrial Park in Ogden. Since then, they have built a second building and have enjoyed being in the space since 2007.

Petersen said their specialty is helping customers get precisely what they need. They work with many local companies for specialty plastic items like Lifetime. They also create products for end users to complete projects. “We do very custom work,” he said.

Streamline Plastics has three divisions – Streamline injection molding, Streamline blow molding and Streamline fulfillment. The divisions define the different kind of plastic work that is done – blow molding is working with plastics with hollow insides, and injection molding is for solid plastic molding. The fulfillment side gives Streamline the chance to tailor specific orders for clients. According to their website, Streamline manufactures specific parts that are assembled and packaged before they are shipped. Services like kitting, pad printing, labeling, hot stamping and bottle filling can be found in the Streamline fulfillment division.

It’s a great time to be in business because many companies like Wal-Mart are finding that they want things to be made in the United States rather than contract with companies in places overseas.

“They are finding when they bid the job, once they pay for shipping, things are just as inexpensive here,” Petersen said. “Now where some companies used to do things 100 percent in China, they are now doing 20 percent,” he said.

Wal-Mart has been a huge boon to their business because they make the small plastic parts to finish work for companies who are working with Wal-Mart. Petersen credits Wal-Mart for helping the pendulum swing to people seeing the value in American-made products. Streamline has seen the shift in the last two years and are working to manage the growth appropriately.

Streamline now has about 30 employees, but that number can increase to 100 when they have bigger projects and hire temporary workers.

Streamline now has about 30 employees, but that number can increase to 100 when they have bigger projects and hire temporary workers.

“We have to be careful to adjust the labor component to the growth rate,” Petersen said. Finding employees can sometimes be a struggle, as Streamline wants to be careful about who they hire. When they find the right fit, though, Petersen explained it can be a real win-win.

“If they come in and want to learn the business, learn how we do things, it can be a great fit. If they have the general ability to learn, we can really teach them,” he added. About 80 to 90 percent of the jobs don’t require a lot of education, but there is priceless on-the-job training, Petersen noted. Because the jobs are always changing – different plastic molding based on customer’s needs, the jobs can be different, which can sometimes be frustrating, but exciting at the same time. And while a lot of the work can be automated, it’s very important to have a great workforce, he said.

Petersen said it has been interesting to watch the industry change and how their business grows at the same time. “We make no parts that we made 10 years ago,” he said. But for them, it’s crucial to not grow faster than they can handle. They want to pace their growth to manage their workforce and never settle for a product that is not exactly what the customer wants.

It can be tricky, Petersen said, but it’s worth it at the end of the day.

“It’s a great time to be in the business because people are seeing how great American-made products are and want to use them,” he said.